In recent years, 3D printing has emerged as a revolutionary technology that has transformed the way we create, innovate, and manufacture. This groundbreaking technology, also known as additive manufacturing, has opened up a world of possibilities, enabling individuals, businesses, and industries to bring their ideas to life in three dimensions. 3D printing services have become the bridge between imagination and reality, offering a wide range of solutions to cater to diverse needs. Whether you’re an entrepreneur seeking to prototype a new product, a medical professional in need of custom implants, or an artist looking to craft intricate sculptures, 3D printing services provide a versatile and efficient means to turn your visions into tangible objects. In this exploration of 3D printing services, we will delve into the myriad applications, materials, and benefits of this transformative technology that is reshaping industries and pushing the boundaries of what is possible.

3D Printing

3D Printing

SERVICE DETAILS

The 3D printing procedure, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from a digital design. Below is an overview of the typical steps involved in the 3D printing process:

- Design: The process starts with the creation of a 3D digital model of the object to be printed. This model is typically designed using computer-aided design (CAD) software. The digital model defines the geometry and specifications of the object.

- Slicing: Once the 3D model is complete, specialized slicing software is used to divide it into thin horizontal layers, sometimes referred to as “slices” or “cross-sections.” Each layer represents a virtual 2D image of the object’s shape at that specific height.

- Material Selection: Choose the appropriate material for the 3D printing process. The choice of material depends on factors such as the object’s purpose, desired properties (e.g., strength, flexibility, heat resistance), and the type of 3D printer being used. Common materials include plastics, metals, ceramics, and composites.

- Printer Setup: Prepare the 3D printer for the printing process. This includes ensuring the print bed or build platform is clean and level, loading the chosen material into the printer’s extruder or material handling system, and configuring printer settings such as temperature and printing speed.

- Printing: The 3D printer reads the sliced data generated by the slicing software and begins the printing process. The printer’s nozzle or print head (in the case of Fused Deposition Modeling, or FDM) or the laser and build platform (in the case of Stereolithography, or SLA) then work together to create each layer. This process is repeated for every layer, with the printer gradually building the object from the bottom up.

- Cooling and Solidification: Depending on the printing technology and material used, cooling or curing may be necessary for each layer. For example, in SLA, UV light is used to cure the liquid resin, while in FDM, the plastic filament cools and hardens quickly after extrusion.

- Support Structures (if required): In cases where the object has overhangs or features that cannot be printed directly onto thin air, support structures may be automatically generated by the slicing software. These temporary structures provide support during printing and are later removed during post-processing.

- Post-Processing: After the printing is complete, post-processing steps may be necessary. This can include removing support structures, sanding or smoothing rough surfaces, painting, assembling multiple printed parts, or performing other finishing touches to achieve the desired final appearance and functionality.

- Quality Control: Inspect the printed object for any defects, dimensional accuracy, and structural integrity. If necessary, make adjustments to the 3D printer settings or the design for future prints.

- Final Product: Once the post-processing and quality control steps are completed, the 3D printed object is ready for use, assembly, or distribution, depending on its intended purpose.

The specific procedures and technologies involved can vary depending on the type of 3D printer and the materials used. However, these general steps provide an overview of the fundamental process of 3D printing.

ABOUT

Welcome to our world of 3D printing services, where innovation meets precision and imagination knows no bounds. We are dedicated to providing top-notch 3D printing solutions that cater to your unique needs, whether you’re a budding entrepreneur, an established business, a creative artist, or a forward-thinking individual. Our 3D printing services open the doors to a realm of endless possibilities, where your ideas and designs can be transformed into tangible, three-dimensional realities.

At Prime Assignment, we understand that 3D printing is more than just a technology; it’s a catalyst for innovation. It empowers you to prototype, customize, and manufacture with unparalleled flexibility, speed, and precision. Our team of experienced professionals, coupled with state-of-the-art 3D printing equipment, ensures that your projects are executed with the utmost care and expertise, delivering exceptional results every time.

In this journey through our 3D printing services, we invite you to explore the diverse applications, materials, and advantages of this transformative technology. Whether you’re embarking on a new product development venture, seeking to revolutionize your industry, or simply looking to bring your creative visions to life, Prime Assignment is your trusted partner in the world of 3D printing. Let’s embark on this exciting journey together, where innovation knows no limits, and the future is built one layer at a time.

Product

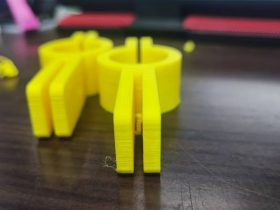

- 3D Plastic Parts

- 3D Toys Model

Custom drawing are welcome to quote

Past Projects

3D Model Printing

Step into a world of creativity and imagination with our specialized 3D printing service that focuses on bringing toy models to life. At Prime Assignment, we’re not just printing objects; we’re crafting moments of joy, nostalgia, and wonder. Our dedication …

Read more

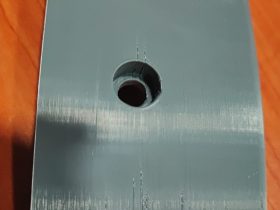

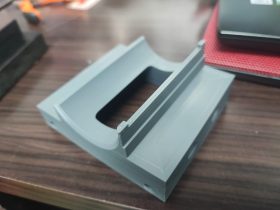

3D Parts Printing

At Prime Assignment, we understand that 3D printing is more than just a technology; it’s a catalyst for innovation. It empowers you to prototype, customize, and manufacture with unparalleled flexibility, speed, and precision. Our team of experienced professionals, coupled with …

Read more